|

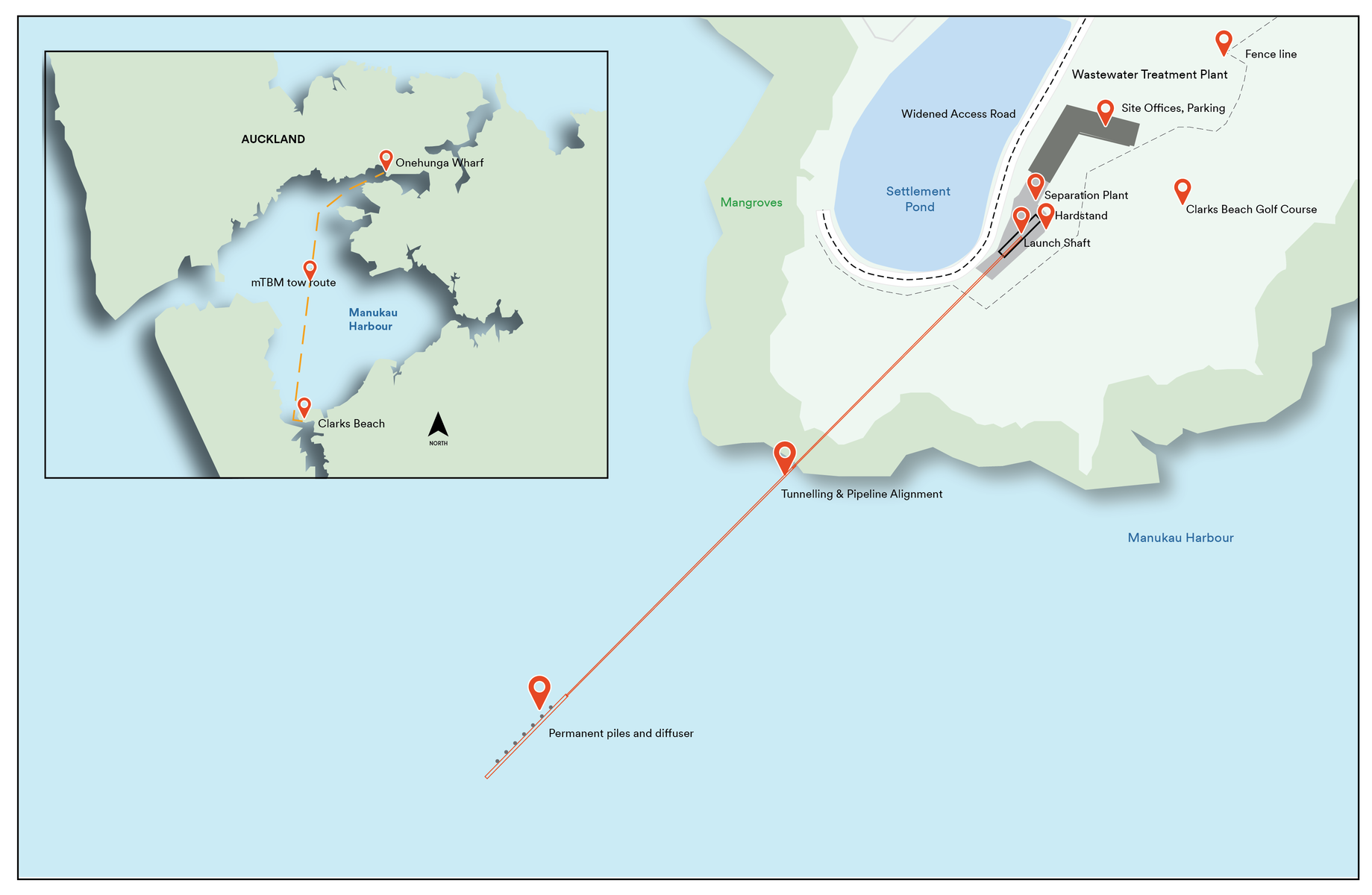

Customer: Watercare Services Ltd Contract: Construct Location: Clarks Beach, Auckland |

Fast Facts:

|

New Zealand's 14th outfall and an eighth Tunnel Boring Machine (TBM) ‘marine recovery’ were completed in late 2025, on time, on budget, with zero Lost Time Injuries (LTIs) and no stakeholder complaints - a 'hole in one' by all the project's key metrics.

Watercare's Clarks Beach Wastewater Treatment Plant, which is located within the Clarks Beach Golf Course in Auckland’s southwest, required a new 240 metre-long outfall.

The key challenges for the project included:

- the location of the treatment plant and the logistics of establishing and operating a construction site within a live golf course

- space constraints within the treatment plant

- the accuracy required to ensure that the works complied with the resource consent

- and a tight programme for the optioneering and design phase to allow the completion of land-based resource consents.

- tide-driven fast-flowing water with minimal slack tide periods at the marine diffuser site.

Why we proposed trenchless tunnelling

Installing the new pipeline using trenchless tunnelling methods was the best option for key stakeholders. Golfers played on while the new pipeline was installed 12 m under the course.

Direct Pipe® could provide the speed, direction control and precision required to position the pipeline. Watercare's hydraulic modelling had identified the exact alignment the outfall needed to work in synergy with the harbour currents and achieve optimal results.

Space was limited within the existing wastewater treatment plant footprint, and as Direct Pipe® can manage all the tunnelling from a single launch shaft, it minimised the construction footprint. The shaft design also decreased the amount of work in confined spaces, reducing health and safety risks.

Direct Pipe® also lowered environmental risk. The variable cutter-head pressure technology it employs decreased the risk of ‘frack out’ or drilling fluid entering the environment. It also significantly reduced the requirement for open-cut trenching in the harbour floor. Rather than having to excavate a 120 m long trench to lay half the pipeline, the TBM was able to drill to the start of the diffuser pipeline, installing it with minimal disruption to the harbour ecosystem. Only a 20m trench at the start of the diffuser pipeline was needed to recover the TBM.

Project milestones

- October 2024 – Enabling works began on-site, establishing robust access roads, laydown areas, worker/golf ball safety netting and constructing a new causeway across an irrigation pond to provide safe access to the site for large plant such as the 110 T crane and the 19.5 T Tunnel Boring Machine (TBM). A robust traffic management plan managed interactions between the construction team, the wastewater treatment plant's operational staff and golf club customers.

- February to April 2025 - The 40 x 10 metre sheet-piled launch shaft was constructed

- 23 April - The 1.3 m diameter Direct Pipe® Herrenknecht TBM was lowered into the shaft and the Direct Pipe® system assembled.

- May - June - In 6 weeks, 240 m of 1.2 m diameter steel casing pipes were installed, half underground and half under the Manukau Harbour sea floor, achieving outstanding productivity rates.

- July - In-house teams designed and fabricated the custom double-pontoon floatation device we used to recover the TBM from the harbour floor. A barge towed the pontoon into place, and divers connected the TBM before it was winched up beneath the pontoon. The barge then towed the pontoon and the TBM 30km to Onehunga Wharf, where it was lifted out of the water.

- July - The 1 m diameter Polyethelene (PE) pipes were progressively welded and winched into the steel casing from the land-based launch shaft.

- July - Oct - Seven permanent steel piles were installed in the harbour floor from a jack-up barge. The team then used a unique modalized method utilising specially designed clamps to install and secure the 66 metre-long PE diffuser pipeline. The pipe has 22 duckbill attachments that help disperse treated wastewater and prevent fish from entering the outfall.

- October – The team demobilised and reinstated the work site well ahead of the programme.

The new outfall was the first project we completed after being selected for Watercare’s Asset Upgrades and Renewals (AUR) Panel in 2024.

The outfall will go online in July, serving up to 30,000 people and supporting long-term growth in Auckland’s southwest.